Important Points To Know About HD-Polymer Materials – Processing And Selection

HD polymers are gaining popularity. The material is best for use in wide applications It has industrial applications. It is also widely used in other areas including the medical industry. The material has unique heat and radiation shielding properties.

• Manufacturers who are concerned about environmental protection often find HD polymer more applicable

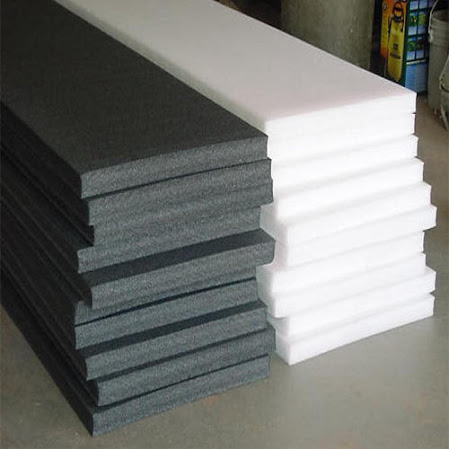

• The material is easy to shape into any possible design

• The polymer has high demand in the manufacturing market

Some unique properties of high density polymers also make it an ideal choice to replace the use of lead. This means that HD polymer material can be used for most applications where is the lead is used.

Two most unique properties

Before you get familiar it the processing and selection, you need to get familiar with the unique properties that make it so different. The first most unique property is that the material is environmentally safe. So even if it is used in frangible ammunitions, it is safe.

Being safe it is also widely used for medical applications. The second property is that when using HD polymer material, manufacturers do not have to increase the material density. It can be used as a lightweight material.

Incredibly strong

Any material that has to be used for industrial applications has to be highly durable. It should be able to resist high impact, temperature and pressure conditions.

This is one of the most unique properties of this material. It is possible to expose the material to high-temperature conditions It can also withstand any level of pressure during the processing stage. This is why the material is ideal for use in all types of injection moulding machines and processes.

Non-toxin

Lead is a highly durable metal. It has been used for various applications because of this property. It does not being melting easily at high temperatures. It can also withstand high-pressure conditions. But when exposed to high temperatures, the lead will be toxic.

But HD polymer materials are non-toxic by nature. It may not burn to produce any toxins. This is why it is safer to use HD polymer in projectiles and ammunition. It offers a very non-toxic formulation process.

Easy to melt

Lead may need to expose to extremely high temperatures before it begins to meltdown. This is important if the metal has to be moulded into any shape. The overall cost of melting lead is also very high.

But polymers are much easier to melt. They may not need to reach extremely high temperatures before they meltdown. This is why it also makes up the best moulding material.

No specialized techniques required

To use lead you may need special techniques. Even when used as Frangible ammunition it is never an easy process.

If you are using HD polymer you may not need to install any specialized techniques. The material can be used in any machine to be processed. The material is also processed in lab conditions. These are only a few important properties why HD polymer is still selected as the best raw material in the manufacturing and shielding industry. It offers more valuable advantages as compared to lead or any other material.

Comments

Post a Comment