Use Of High Density Thermoplastic For Sustainable Lead-Free Components

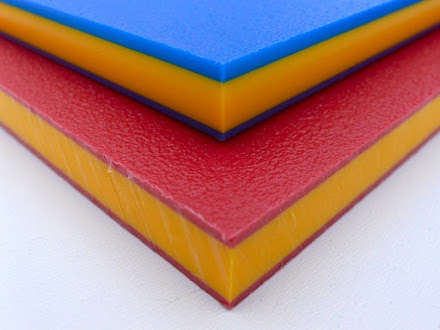

The high density engineered thermoplastic material is sustainable and non-toxic material readily used for construction of wide range of products. With its outstanding benefit, it has helps in reducing the toxic metals and components like lead. The products are designed through various procedures like compression molding or injection using the engineered thermoplastic.

The high density plastic is used for manufacturing a range of products like ammunition, radiation shielding devices for medical purpose, vibrational dampening , balancing components etc. It is widely used in design wide range of OEMs and material processors without the presence of the lead.

Benefits of Using the High Density Thermoplastics for Product Application

The properties of the high density thermoplastic make it suitable for production of wide range of products. Previously lead was used in the manufacturing of industrial products but it caused toxicity and adverse effect. The thermoplastics are sturdy and strong with outstanding sustainable properties.

• It has high gravity and density which adds higher value and weight to the products and OEM components. This helps in retaining the shape and prevent distortion.

• It is an incredible lead substitute and hence prevented the toxicity caused by use of lead and other toxic metals. With the use of high density thermoplastic, it makes the component eco-friendly and sustainable.

• Thermoplastic is strong along with high tensile strength. It helps in ease of production of the component as it is moldable and hence can provide flexible design.

• The process of production of different components is convenient with the moldable properties. The material take shape of any component through compressible or injectable molding method.

The products and OEM components are not only eco-friendly but affordable. As it has high strength and durability, it is resistant to adverse condition. The strength and density of the product provide high performance and longevity for the products.

Use of the Thermoplastics and Production of Safe Products

The high density thermoplastic is used in production of multiple products. It helps with the production of safe radiation device and medical devices which helps in shielding against the X-ray and the gamma rays. It helps in maintaining the regulatory standard and prevents from direct radiation.

The lead free radiation shielding medical are safe as it prevents the patient and medical professional from coming in direct contact with radiation. The shielding is optimized by customizing the material density as well as the thickness of the component. It is used in industry, medical X-devices as well as even in nuclear plants.

Production of Eco-Friendly and Moldable Components

Vibration can impact productivity and create a lot of disturbance. The lead free thermoplastic helps in dampening the vibration. The high density thermoplastics are suitable for dampening or isolation of vibrations. It is used for designing components for reducing the energy produced by the machinery.

The thermoplastic are suitable material for development of eco-friendly ammunitions. The frangible bullets from high density thermoplastic are safer alternative and does not release toxic elements. It helps with the production of the green bullets and hence makes it toxic-free without lead.

Comments

Post a Comment