Could The Use Of HD Polymers Help In Shielding Radiation?

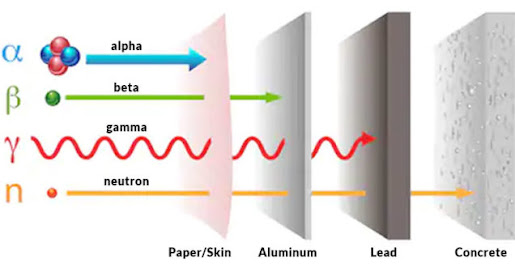

Radiation can pose a serious impact on the body cells Radiation shielding is important in many industrial applications. Overexposure to radiation can be prevented. Traditionally heavy metal like lead was used as an effective radiation shielding material.

? Sources that can lead to radiation exposure

There are many different applications- industrial and commercial that can result in exposure to radiation. Space exploration programs, nuclear waste storage units, medical imaging units, medical therapies and food sterilization units are some examples.

These are the places that are high in ionization radiation energy. Working in these places can pose a serious threat to your life. Thus radiation shielding materials are commonly used in these places.

• Overexposure to radiations can impact the functioning of internal body organs

• It can lead to permanent organ and body cell damage

• It can also lead to the malfunctioning of mechanical components

The high-density polymer material is considered the best alternative to expensive lead metal. The material helps in offering the best shield against harmful radiation.

? How do high-density polymers work?

High-density polymer materials are made up of heavier atoms. The atoms will prove helpful in scattering the radiation particles. The atoms in this polymer will help in absorbing the radiation particles.

This is why industries are making use of quality polymer material in radiation producing machines including x-ray scanners.

? High-density polymers attenuate radiation

Lead and other heavy metals that are used for radiation shielding will have atoms with high mass numbers. Some common heavy metals include stainless steel, copper and lead. These metals are also expensive.

High-density polymer materials are made to replicate heavy metal atoms. Thus they will attenuate the energy produced by the radiation. This helps in reducing the toxicity produced by the radiation energy.

? Polymers are non-toxic

Lead and any other heavy metal is toxic by nature. The moment the atoms will absorb radiation energy, they get toxic. This poses serious health hazards for any staff member who is working within the short-range.

Industries have started using high density polymers as the best replacement for heavy metals. HD polymers are non-toxic by nature. They do not harm your health even when they come in contact with high energy radiation.

? Minimizes radiation exposure

HD polymer materials are used as raw materials in radiation producing machines. The polymer material will block the path of the radiation energy.

This will reduce the effect of the radiation as the passage of the energy is blocked. Thus the polymer material makes up the best shielding material for use in x-ray and other machines that produces radiation. The polymer is also best for use in tomography machines.

? Polymer works very much like ceramic

The most important property of HD polymer material is that it works very much similar to ceramic material. It does not allow the radiation energy to penetrate through it. Thus polymer material will completely absorb the heat energy produced during the chemical reaction as well.

This type of material is widely used in the making of semi-conducting devices, magnetic cards and optical components that produce radiation energy.As compared to lead, HD polymer material is more cost-effective and easily available.

Comments

Post a Comment