The Ultimate Uses Of Heavy Plastics Materials For Different Purposes

Many of the established forms are showing a huge interest in using recycled plastics for several purposes. The increasing popularity of global plastic sheeting is becoming the foremost choice for many people as it is considered to be more flexible and rougher by nature.

Let’s Know the Deeper Fact About Thermoplastics:

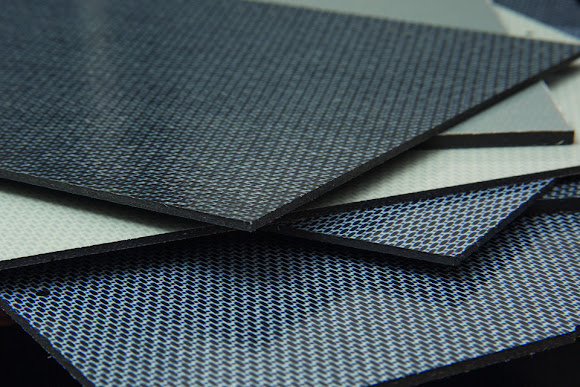

Another term is also considered as the most commonly used one of the most initial decking building materials. Presently, many of the top companies are involved in the development and production of thermoplastic composite material that can be known as the best class of building modern materials.

In the current time, the use of high-density heavy recycles plastics is delivering more attractive solutions for many reasons. In the building materials, the rising demand for reinforced and composite products is heading many projects.

How the Modern Durable Thermoplastics Made Off?

In the generic term, the entire process of thermoplastic is called as heat- melt impregnation process, through the help of this process all types of thermoplastics composites face sheets are made off properly.

Many of the companies are used CSIP for making thermoplastic composite products it combines with resin elements also. In some of the car manufacturing units, the high demand for composite materials is growing day by day.

With the help of high or heavy plastics resistant polyamide ribbon is well recycled with a high level of the heating process along with continuous carbon fiber. The present automobile industry is making some incredible composite auto parts with the help of robots.

The robots help them in keeping the desired thermoplastics tape in the accurate position and then hot-stamp them efficiently to make in shape and durable by the heavy process. The ultimate result of this stamped parts with high temperatures and they are used in making a brand-new car.

Advantages of Using Thermoplastics Composite Products:

• IT is useful in a wide range of different products for multiple purposes

• It is a very lightweight product

• The products generated from it are more durable

• They are also considered as easy to produce

• The overall investment cost is low

All the advantages are attracting the manufacturing companies to add thermoplastic production as one of the most demanding industry as of now. In the aerospace sector, they are also high in demand due to energy efficient products can be easily generated and recycled them properly.

Another foremost feature of the thermoplastic products is that they can be manufacture with minimal investment, in another way we can say that it is relatively energy efficient in both the way like manufacturing and processing it.

Some of the most recommended examples of Thermoplastics are:

It is one of the most durable products and is known by the different types in different applications. A good example of thermoplastic materials is polyethylene, polyesters, polyamides, polyvinyl chloride, and many more.

They are not much harmful if we look into the environmental point of view; most of the products which are using these thermoplastic materials are helping actually to live in a more environmentally friendly way and can be more efficient in food packaging, fuel energy-efficient, lightweight products, etc.

Comments

Post a Comment